Bonding

|

|

Assembled parts with metal and insulated ceramic by solder

|

It is possible to assemble each part with solder, which is processed by our micro machine processing and metallization.

Solder type: AuSn, AuGe, AgCu etc. |

| |

|

|

|

|

|

| Mounts/carriers |

|

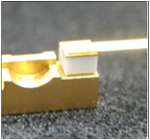

Carriers for optical communication |

|

|

| |

| |

| |

Products processed by this technology

|

|

|

| |

|

| |

|

|

|

|

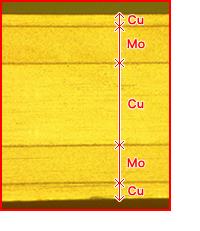

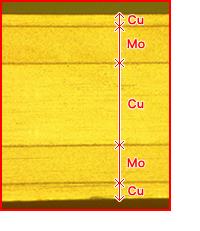

| This product has seven-layer of Cu and Mo which are formed into a 1.6 mm thickness, leading to the control of CTE less than 8 ppm/K. The two technologies below are applied. |

| ・Three-layer forming of central Cu-Mo-Cu by electroforming |

| ・Seven-layer forming into the thickness with the three-layer above, bonded by AuSn solder |

|

|

|

|

| |

|

|

| |

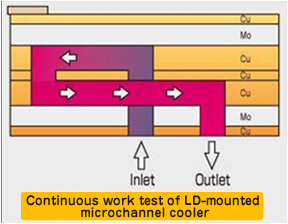

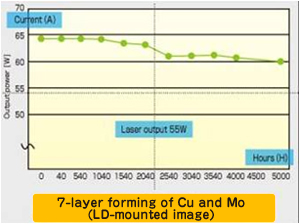

| With the technologies above, our customized microchannel cooler with LD-mounted on has achieved 5,000 hour endurance time in a continuous work test. |

| |

|

| |

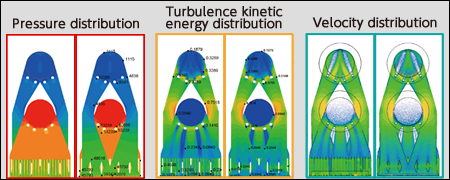

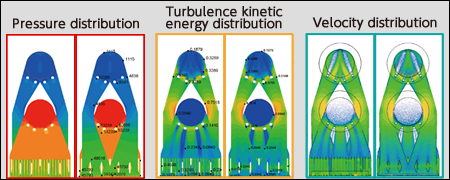

| We have optimized pressure distribution, turbulence kinetic energy distribution, and velocity distribution for our standard products by simulating various microchannels on a design stage. Those can be re-designed according to customers’ needs. |

| |

| |

| |

Products processed by this technology

|

|

|

|

|

|

| |

| |

|

| |

|

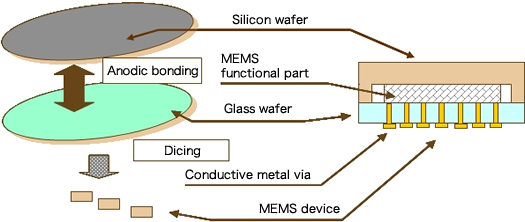

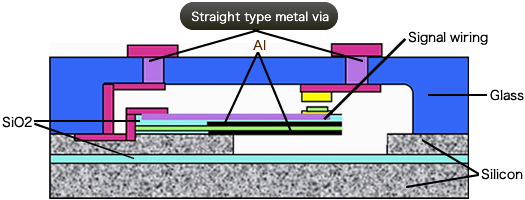

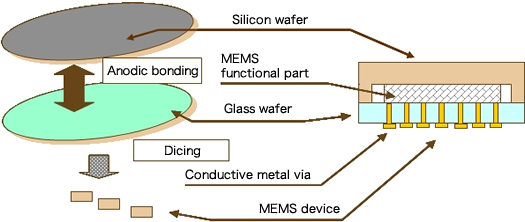

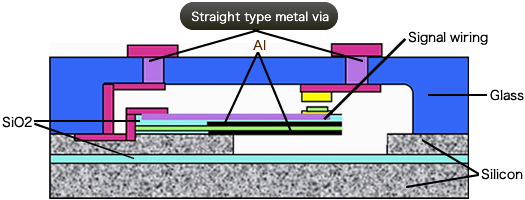

Conductive-through-metal-via processing

|

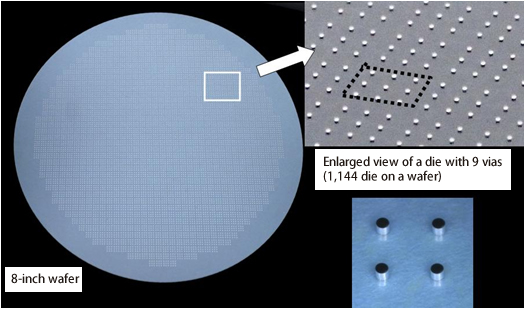

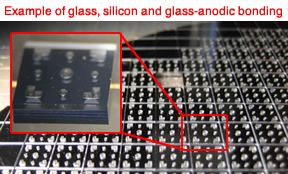

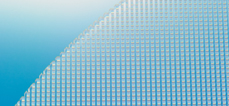

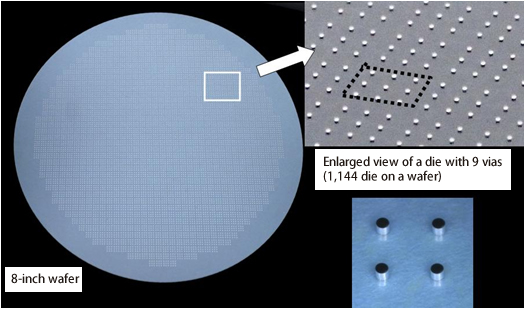

| This borosilicate glass wafer has a large number of through-conductive-metal-vias, which gives it electrical conductivity. The maximum size of wafer is φ 200 mm. Anodic bonding can be applied to seal a silicon device. |

| |

|

| Through glass via(φ0.3mm、10,296 vias) |

| |

|

| |

|

| Example applied for RF-MEMS switch |

| |

| |

| |

Products processed by this technology

|

|

|

| |

| |

|

| |

|

|

|

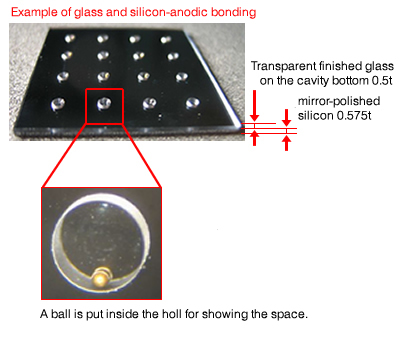

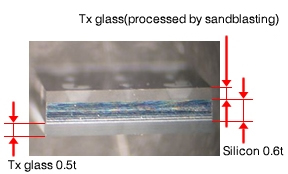

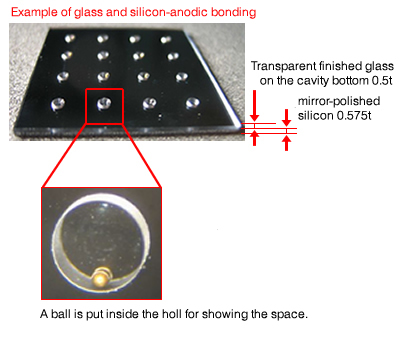

| Anodic bonding is the bonding method where heat and voltage are applied to the borosilicate glass and silicon. It can achieve high-quality bonding because adhesive or solder is not used in the process. |

| |

|

|

| |

|

| |

|

| |

| |

| |

Products processed by this technology

|

|

|

| |

| |

| |

|

| |